For decades, mine operators have relied on site visits to bring investors, regulators, and community leaders “into the operation.” The thinking was simple: seeing the mine first-hand builds confidence.

But mine site visits are disruptive. They take crews offline for days to escort visitors. They introduce safety risks to people who aren’t trained to be underground. And ironically, they don’t always give visitors a clear picture. Stakeholders might see a truck drive by or a conveyor in motion — but they rarely see the bigger system at work.

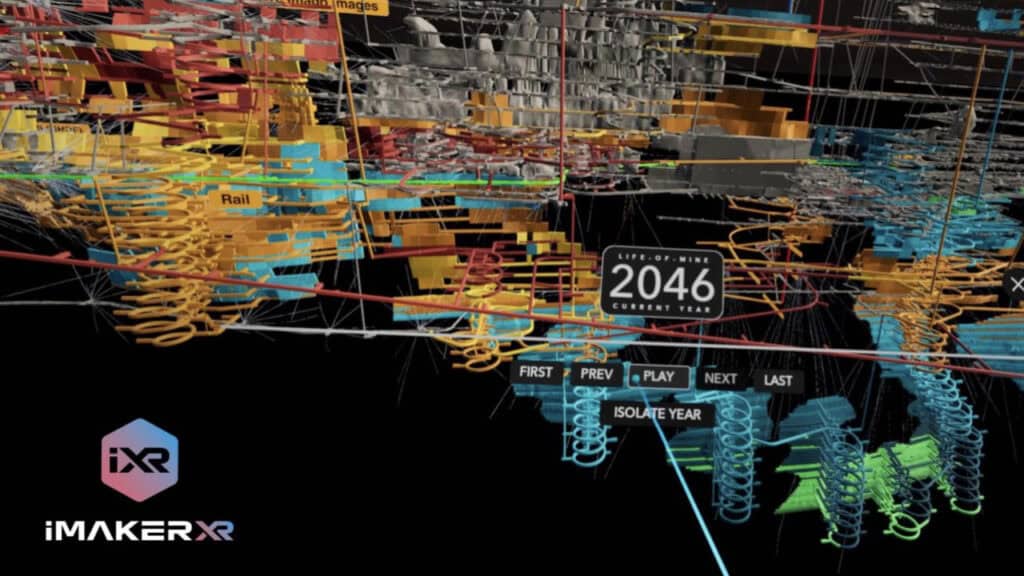

At one copper mine, the leadership team faced this challenge head-on. Instead of flying in dozens of stakeholders, they built a digital twin of their site and used advanced visualization to host a virtual mine site visit.

From an investor’s office in Toronto to a regulator’s desk in Santiago, participants logged in and experienced the mine in motion:

And unlike a traditional site visit, they weren’t limited by what they could see from a viewing deck. They could “walk” anywhere in the operation — above ground, underground, or even inside the plant.

The result was powerful. Investors came away with a system-level view of how production, safety, and sustainability fit together. Regulators could visualize compliance safeguards with clarity. Community representatives saw environmental measures in action, not as bullet points in a report, but as living, visible systems.

For the mine itself, the benefits were clear:

The role of the three twins

This kind of virtual site visit is made possible by what iMakerXR calls the Sales & Marketing Twin — a digital twin designed to communicate complexity with clarity. But it’s only part of a larger ecosystem:

Together, these twins create a 360° lens on mining, one that shows the operation not just as it is, but as it could be.

Behind the virtual tour, expert AI agents were quietly at work. A Safety Agent highlighted hazard zones. A Performance Agent annotated fuel savings from optimized haul routes. A Compliance Agent flagged ESG safeguards in real time.

Facilitator agents wove these threads together, giving participants a guided narrative: “Here’s how operational efficiency ties to environmental performance.”

And over the top of it all, a reasoning model helped leaders explore trade-offs in plain language: “Show me the lowest-cost plan that still meets emissions targets.”

The result wasn’t just a tour, it was a dialogue with the mine itself, powered by digital twins and intelligence working together.

Mining companies no longer have to choose between disruption and clarity. Virtual site visits deliver more understanding, to more people, with fewer risks and costs.

Investors gain confidence. Regulators see transparency. Communities feel heard. And operations stay on track.

Because sometimes the most powerful visit is the one that never happened, and left everyone with a clearer picture of the mine.

I’m Al Asghar, Senior Account Manager at iMakerXR. Our team helps mining companies and industrial leaders transform complex operations into immersive 3D experiences that engage investors, regulators, and communities.

📩 Connect with me directly at al.asghar@imakerxr.com or explore more at www.iMakerXR.com.